Countercurent bleaching of rapseed oil

P. Transfeld

ÖHMI Aktiengesellschaft

Berliner Chaussee 66

D—39114 Magdeburg

Germany

Phone [049] (391) 85 07—155

Fax [+49] (391) 85 07—150

e-mail oehmi@t-online.de

http://www.oehmi.de

Abstract

Countercurrent bleaching is a process which saves 40% of bleaching earth. These results are achieved even by a two-stage process.

In the first stage, the unbleachd oil is bleached with bleaching earth that has already used once. In the second stage, the prebleached oil is finish-bleached with fresh bleaching earth.

The method is particulary suitable for bleaching dark oils such as rapseed oil.

This paper reviews the progress made by ÖHMI.

1. Indroduction

The countercurrent principle gained wide acceptance in many technological processes from early on. However, a long time passed before it was used in the bleaching of vegetable oils. Although the first basic research had already been carried out in the 1930s, the first regulary operating industrial facility was commissioned by ÖHMI in 1995.

Why did it take seventy years from conception of the idea to ist realization?

— technical solutions for hermetically sealed separation and transportation of the spent bleaching earth were not yet available,

— for a long time the opinion was that the advantage in savings is canceled out by the amount of equipment required,

— and for a long time the so-called “press effect“, where the unbleached oil is run throuhg a filter press, was regarded as the optimal and practicable solution.

But we have been concerned with these questions (TRANSFELD 1986, 1987, 1988, 1989) since 1983 and have come up with the following solutions.

2. Laboratory Results

As we have reported on various occasions, bleaching earth savings of more than forty percent are archieved under certain circumstances. The exemplary experiment makes use of a three-stage countercurrent cascade.

A great deal of equipment is required as there is complete phase mixing and separation, i.e. three bleachers and three filters.

There are no prospects for success when applied directly on an industrial scale.

However, as we find, there is a seventy-five percent reduction of undesired oil companion substances in the first stage. This means that bleaching earth which has already been used once continues to possess a significant absorptive capacity.

And now for the other fundamental conclusion of our research in the laboratory and on a pilot-plant scale.

— bleaching earth savings depend on the course of the absorption isotherm, i.e. in particular on both the type of oil and the type of bleaching earth,

— oils having a high amount of undesired accompanying substances provide for particulary high bleaching earth savings,

— the two-stage process is the most economical form of using countercurrent bleaching,

— the procedural parameters of temperature, time of contact and the addition of water and acid determine success and the amount of savings,

— provision must be made for hermetically sealed intermediate separation and transport of the used bleaching earth,

— the process is successful in the case of alkaline refining and, particulary, physical refining.

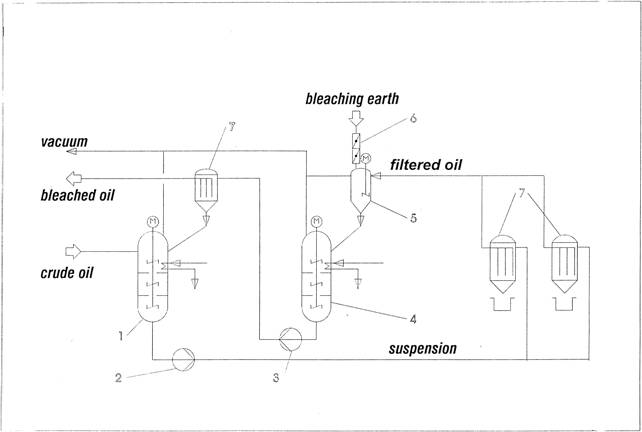

3. Scaling (figure 1)

The fundamental priciple of ÖHMI bleach®, as we have termed the process, is rather simple.

In the first phase, so-called pre-bleaching, unbleached oil is brought into contact with bleaching earth which has been used once. In the second phase, so-called final bleaching, bleached oil is brought into contact with fresh bleaching earth.

The second separation phase represents an important step, whereas the bleaching earth which has already been used once is separated for a second application.

This is done in a special filter.

The constituents are obtained as a pumpable sludge. In the first stage they are passed to the uncleaned oil with air excluded.

We have patented this solution worlwide.

We established the first industrial facility at Walter Rau AG in Neuss, Germany, in 1995.

The flow rate amounts to 250t of oil per day. The facility is completely automated. Palm oil, soybean oil, coconut oil and rapseed oil are proccessed. The specified quality and stability parameters of the oil are reached reliably.

Bleaching earth consumption is reduced by more than 40%. The volume of filter cake to be disposed and the oil losses are also reduced by 40%.

Quality and stability parameters of the oil satisfy standard requirements. The process is suitable for any oil. The process can be integrated easily into existing plants. It is used without any restrictions for alkaline and physical refining.

What is the basis of these results, what is of fundamental importance?

The bleaching earth which has already been used once and is obtained as pumpable sludge, still has a very high adsorptive capacity. 75% of undesirable admixtures contained in bleaching oil are adsorbed.

The secund industrial facility was established in 1998 in Indonesia. Presently, countercurrent systems are prepared and constructed in various countries.

figure 1

4. Conclusion

— Both laboratory research and pilot-plant studies have shown that approximately forty percent of bleaching earth are saved by using the countercurrent bleaching principle.

— These results were successively implemented on a commercial scale.

— Quality and stability parameters of the oil satisfy standard requirements

— The process is suitable for any oil

— The process can be integrated easily into existing plants

— It is used without any restrictions for the alkaline and physical refining.

5. References

P. Transfeld, Dissertation A, Universität Otto von Guericke Magdeburg (1986)

P. Transfeld, Lebensmittelindustrie 33 (1986), pp. 125—129

P. Transfeld, Lebensmittelindustrie 34 (1987), pp. 224—227

P. Transfeld, Lebensmittelindustrie 36 (1989), pp. 204—207

P. Transfeld, Lebensmittelindustrie 35 (1988), pp. 276—279